This article is based on service information Kolbenschmidt 50003717

RELATED TOOLS AND INSTALLATIONS:

| Kolbenschmidt no | Name |

| 50009824 | Feeler gauge |

| 120000316001 | Piston ring pliers |

| 50009829 | Truck piston ring pliers |

| 120000416353 | Pas. car piston ring scuff band, 3"" ta |

| 120000416490 | Ut. veh. piston ring scuff band, 4" ta |

| 120000116900 |

Piston ring service tool set |

| HP0009 | ET Engineteam Pas. car piston ring scuff band, 3"" ta |

| HP0013 | ET Engineteam Piston ring pliers |

| HP0014 | ET Engineteam Piston ring service tool set |

Preparation

Cleaning the pistons

First, clean the pistons thoroughly and remove all traces of oil carbon from the ring grooves. Remove the carbon from the oil return bores using a twist drill and tap wrench; clean the grooves without damaging the groove sides. Replace cracked, collapsed and worn pistons.

Cleaning the cylinders

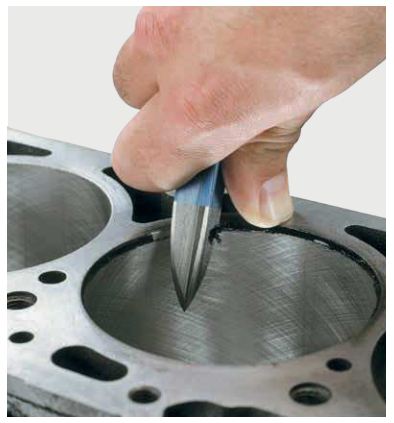

Remove carbon residue from the top area of the cylinder bore that shows no wear.

Inspection

Inspecting the piston ring grooves

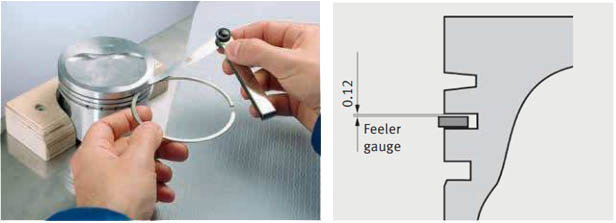

If a distance of 0.12 mm or more is measured between a new, parallel-sided compression ring and the corresponding groove side, the piston is excessively worn and must be replaced.

Measurement of the piston ring grooves with a feeler gauge. Kolbenschmidt article no. 50009824

| Groove clearance | Usability of the pistons |

| 0.05 – 0.10 mm | Pistons can be used without concern |

| 0.11 – 0.12 mm | Increased caution is required |

| > 0.12 mm | A new piston must be used! |

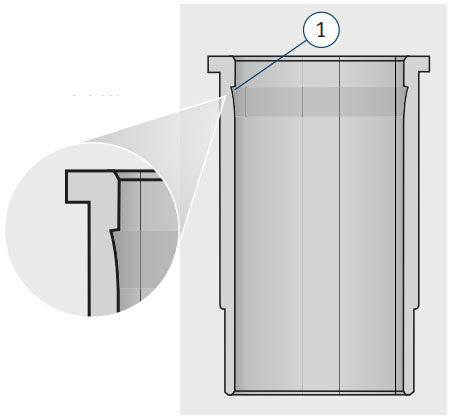

Inspecting the cylinder wear

If the cylinder wear is greater than 0.1 mm in petrol engines and 0.15 mm in diesel engines, the cylinder must be replaced (top ring reversal bore wear).

1 Top ring reversal bore wear

Checking the piston ring set components

When replacing the piston rings, we always recommend replacing a complete set. Check the ring height by means of a caliper. When doing so, a comparison with our catalogue data is recommended.

The diameter can be checked using a measuring ring or reworked cylinder; the joint clearance based on a subjective assessment or with a feeler gauge. When checking the ring diameter in worn cylinders/cylinder liners, note that the joint clearance can assume larger values.

Installation

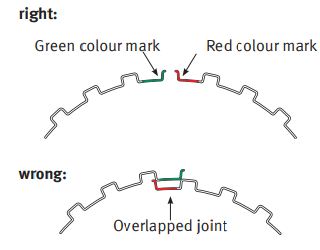

Mounting piston rings

Insert the piston rings into the respective piston ring groove with the correct itting tool. Excessive spreading of the piston rings during mounting is to be avoided, as this causes permanent deformation and afects the performance of the piston rings. The "TOP" marking must point to the piston crown so that the scraping action is directed towards the skirt end. In the case that the piston rings are not mounted accurately, the function of the ring set unit is no longer immaculate. In severe cases, incorrect installation of the piston rings will cause the oil from the crankcase to be pumped into the combustion chamber.

Piston ring pliers Kolbenschmidt no. 120000316001 for ø 50 – 110 mm Kolbenschmidt no. 50009829 for ø 110 – 160 mm

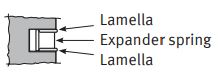

Mounting oil control rings

With three-part oil control rings, there are versions for which the spring elements on both joint ends are marked with coloured dots. Both coloured dots must still be visible on the support spring after mounting the rings. This guarantees that the two ends of the spring do not touch one another or overlap.

Installation recommendation:

When mounting the spiral expander rings, the joint ends of the spiral expander must always be positioned exactly opposite the ring joint. For spiral expanders with a Telon sheath, the sheath rests on the ring joint.

Function test

After installing the piston rings it must be ensured that they can move freely. Rotate the joint ends of the piston rings on the piston by 120°.

Note: With two-stroke engines, the piston rings are often secured against twisting by a pin. These must not be twisted, as this can cause the securing pin to move below the piston ring sprung outwards in the area of a cylinder window and break this of at the opposite window edge.

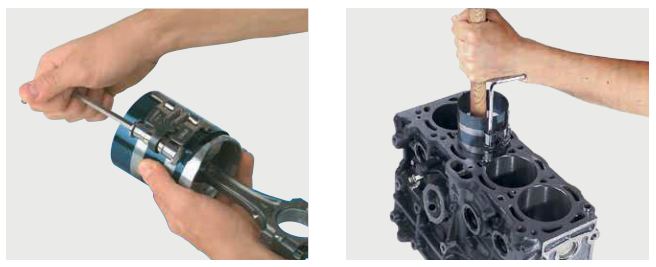

Inserting the piston

Suiciently oil piston rings and pistons and install with a closing piston ring clamp or a conical assembly sleeve to prevent the piston rings from being damaged.

Attention: Chrome-plated piston rings must not be built into chrome-plated cylinder liners.

| Warehouse: | 2 pcs | |

| Supplier: | 25 pcs |

| Warehouse: | > 25 pcs | |

| Warehouse 2 (+3 days): | > 25 pcs |

| Warehouse: | > 25 pcs |

| Warehouse: | > 25 pcs |

![$languages[$currentLang]->langNam](/images/flag/gb.png)