The main purpose and benefit of the variable valve timing is to optimize the engine performance in every situation, improvement of the engine and lowering of the exhaust emissions. All this above in synergy with control unit.

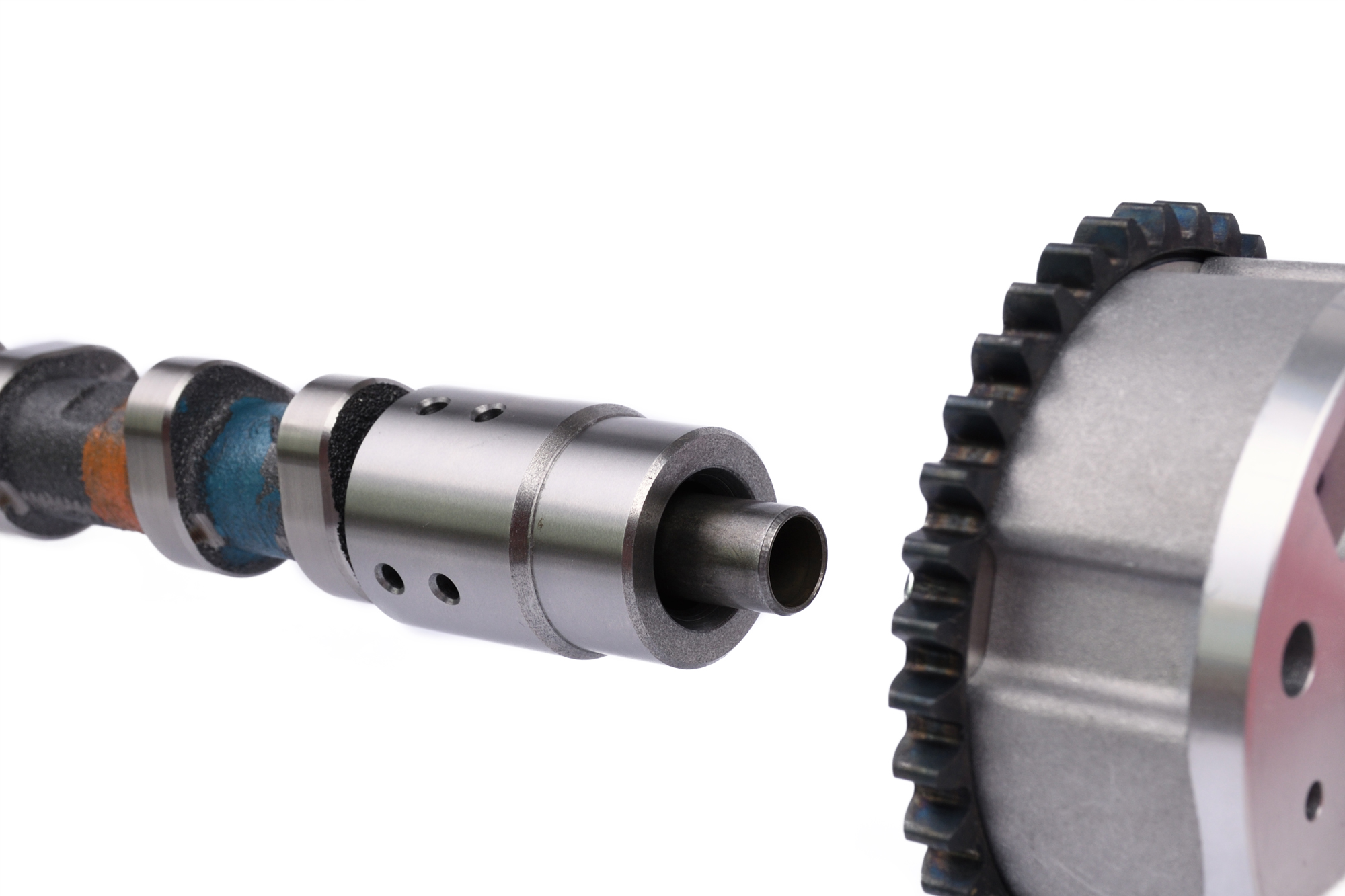

Variable valve timing consists of rotor, stator and locking pin. It is controlled via oil valve. Stator is connected with timing gear, rotor is connected to suction shaft. Oil valve is sometimes connected to the camshaft or it is on the cylinder head cover.

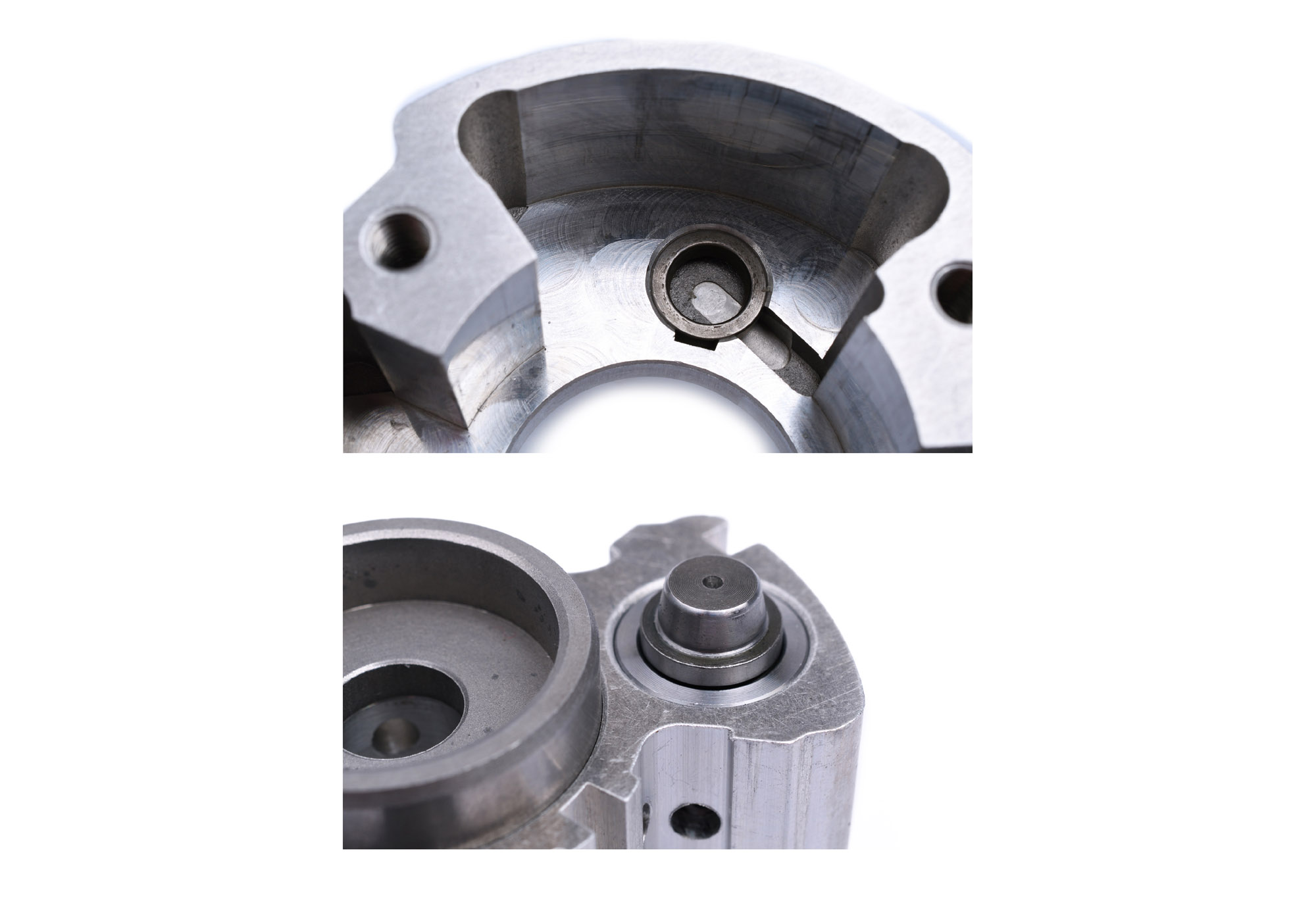

Pic. 1: Variable Valve Timing: Rotor with locking pin (bellow) and stator of VVT hub

Pic. 2: Stator is connected to the gear; detail of camshaft adjuster:

Pic. 3: Rotor is connected to the camshaft

How does VVT work

For the right functioning of the VVT the Control unit is evaluating states of the air controller and speed sensor. To correct the functions it uses the information from a cooling liquid temperature sensor and for sensing the position of the intake of the camshaft it uses Hall effect sensor.

When the engine is off the VVT is in late (inactive) position locked with blocking pin, which releases after the oil pressure gets up. Hub stays in this position even after the engine start and low rpm up to 1800 rpm. With higher rpm and after the evaluation of all the information the control units send the PWM signal to the electromagnetic valve.

Pic. 4: Locking pin detail (below) with lock pin vent and engine oil conduit:

After the change of the electromagnetic field the electromagnetic valve forces the split valve, which allows the way for the oil to get into one of the chambers of the hub and it will adjust the camshaft. Position of the shaft will change (mostly for 30° or 60°; it can differ depending on the engine type or car type) which will affect the time and period of the opening and closing of the valves. The outcome is better engine performance with higher rpm or on the other hand fuel saving while low rpm.

Pic. 5: Individual parts of the variable valve – movement of rotor after the oil pressure change will adjust the shaft:

In case of the VVT hub malfunction the adjuster will switch into the inactive position in which stays for the whole period of the problem. OBD diagnostic then indicates problem with timing which might be caused by several things. The outcome is VVT hub remaining in the inactive position.

| Warehouse: | > 25 pcs | |

| Warehouse 2 (+3 days): | > 25 pcs |

| Warehouse: | 9 pcs | |

| Warehouse 2 (+3 days): | > 25 pcs |

| Warehouse: | > 25 pcs |

![$languages[$currentLang]->langNam](/images/flag/gb.png)