Dirko™ HT red (acetic curing) is a high-quality, high temperature resistant single component silicone-based sealing compound that exhibits permanently resilient properties. It provides excellent adhesion on all standard metals, cast iron, plastics (except for PE, PP and PTFE) and glass. Due to a reaction with humidity in the air Dirko™ HT red cures to form silicone. The product can be used for a very wide range of applications.

1. General product infomation

- Chemical basis - Acetoxy silicone

- Curing - Room temperature vulcanised (RTV)

- Components - Single component

- Colour - Red

- Consistency - Pasty, stable, permanently resilient when cured

- Temperature range - -60°C to +300°C (for 24h up to +315°C)

- Maximum sealing gap - 2,0 mm

- pH value - Neutral

- Electrical conductivity - Insulating

- Resistant to - Mineral oils (including additives), synthetic oils, Lubricating grease, Coolants, UV radiation , cold and hot water, salt water , cleaning agents, weak acids and alkalis

- Possible applications - valve cover, oil pan , water pump , oil pump , diff, rential housing , gearbox, gear oil sump , thermostat housing , control housing , axle cover, lange connection , headlights, rear light , battery compartment

2. Technical data

2.1 General properties

|

Measured variable |

Value |

Test standard |

|

Shore A hardness |

30 ± 5 |

DIN 53505 |

|

Density |

1,1 ± 0,2 g/ml |

DIN 53479 |

|

Skin formation time (23°C, 50% relative humidity) |

5 - 10 min |

DIN EN ISO 291 |

|

Curing time (23°C, 50% relative humidity) |

ca. 4,5 mm / 24 h |

DIN EN ISO 291 |

|

Elastic modulus 100% |

0,6 ± 0,2 N/mm² |

DIN EN ISO 8339 |

|

Elongation at break |

600 ± 100 % |

DIN 53504 |

|

Tensile strength |

2,9 ± 0,2 N/mm² |

DIN 53504 |

2.2 Media resistance

To demonstrate the media resistance of the sealing compound, the test specimens are stored in the relevant medium for the specified duration. The tensile shear strength is then determined (ISO 4587). The following table shows the percentage variation in the tensile shear strength from the initial value without the influence of the medium.

|

Medium |

Property |

Temperature (°C) |

Variation from initial value (%) |

||

|

250 h |

500 h |

1000 h |

|||

|

Air |

Elongation at break (%) |

250 |

-2 |

4 |

31 |

|

Tensile strength (N/mm²) |

250 |

44 |

43 |

32 |

|

|

Elongation at break (%) |

285 |

50 |

62 |

83 |

|

|

Tensile strength (N/mm²) |

285 |

1 |

-15 |

-20 |

|

|

Engine oil |

Elongation at break (%) |

120 |

21 |

33 |

45 |

|

Tensile strength (N/mm²) |

120 |

-9 |

-15 |

-50 |

|

|

Water / glycol (50/50) |

Elongation at break (%) |

95 |

1 |

11 |

-12 |

|

Tensile strength (N/mm²) |

95 |

84 |

87 |

69 |

|

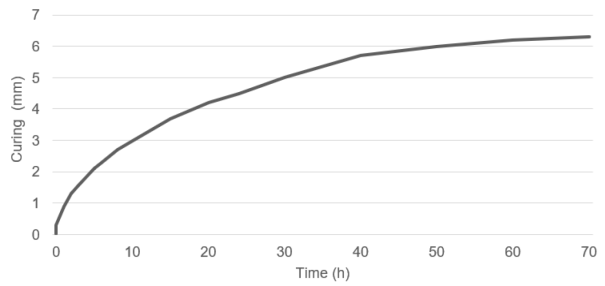

2.3 Curing rate

The curing rate depends on the temperature and humidity. The higher the temperature and the humidity, the faster Dirko™ HT red cures to form silicone. The lower diagram shows the progression of the curing rate over time in a standard climate (23°C/50% relative humidity).

2.4Surface adhesion

The adhesion of Dirko™ HT red on different surfaces plays a crucial role in its use as a surface seal. The following figures show the measured tensile shear strength for a sealing gap of 1 mm (ISO 4587).

|

Surface |

Tensile shear strength [N/mm²] |

|

Steel (galvanised) |

0,90 |

|

Aluminium |

2,00 |

|

Polyamide 6.6 |

0,60 |

3. General information

3.1. Usage and processing instructions:

- Remove sealant residues and clean the sealing surfaces with solvent.

- Sealing surfaces must be clean, dry, and free of oil or grease before applying the sealing

compound in order to ensure reliable sealing and adhesion. - Processing temperature (ambient / adhesion surface temperature): +5 to +35°C

- Apply the sealing compound evenly across the entire surface.

- Immediately remove any excess sealing compound applied, as there is a risk that it could

drip into the interior. - Depending on the application, the parts can be fitted immediately after application, after

skin formation or after complete curing. - Fit the components in line with the manufacturer’s specifications.

- The sealing function is immediate.

- After use, reseal the sealing compound securely.

- Safety and technical data sheet at www.elring.com

3.2. Storage

- Optimum storage conditions: Cool (+5°C to +25°C) and dry location

- Minimum shelf life: 24 months in unopened containers. .

Seal opened containers securely and use up as soon as possible.. - The batch number has the following structure: YYWWCCCCC (filling date)

3.3. Delivery form

|

Item no. |

Package content |

Volume |

colour |

Packaging unit |

|

Tube, Tube key, nozzle |

70 ml |

Red |

12 units |

|

|

nozzle, Compressed gas cartridge |

200 ml |

Red |

12 units |

3.4. Exclusion of liability

The above specifications in this technical data sheet, in particular the suggestions for processing and usage of our products, are based on our current knowledge and experience. As a result of the varied possible uses and the fact that the usage and working conditions are outside our area of influence, we accept no liability for the suitability of our products for a particular production process under specific working conditions, or for the intended processing purposes and results. To ensure suitability, we recommend that adequate independent trials and tests are always performed in advance.

Any liability resulting from the information in this technical data sheet and from other written or verbal advice for the product in question is explicitly excluded, unless a case of injury, death or health problems arises that is due to intent or gross negligence on our part, or we are subject to liability under mandatory product liability law.

This article is based on service information "Dirko™ HT (red)"

General information

| Code: | 705.708 |

| Brand: | ELRING |

| Title: | Sealing Substance |

| Car: | UNI Dirko HT 70ml |

| Weight : | 0,11 kg |

Criteria

| Chemical Properties: | Permanently elastic |

| Chemical Properties: | not solvent-bearing |

| Chemical Properties: | UV resistant |

| Packing Type: | Tube |

| Capacity [ml]: | 70 ml |

| Material: | Silicone |

| Temperature range from [°C]: | -60 °C |

| Temperature range to [°C]: | 315 °C |

| Colour: | red |

| Warehouse: | > 25 pcs |

General information

| Code: | 465.766 |

| Brand: | ELRING |

| Title: | Sealing Substance |

| Weight : | 0,47 kg |

Criteria

| Chemical Properties: | Permanently elastic |

| Chemical Properties: | UV resistant |

| Chemical Properties: | not solvent-bearing |

| Packing Type: | Cartridge |

| Capacity [ml]: | 310 ml |

| Material: | Silicone |

| Temperature range from [°C]: | -60 °C |

| Temperature range to [°C]: | 315 °C |

| Colour: | red |

| Warehouse: | 0 pcs | |

| Supplier: | Check |

![$languages[$currentLang]->langNam](/images/flag/gb.png)